Straw pellet machine production line straw pelletizer

Biomass fuel is the use of corn stalks, wheat straw, straw, peanut shells, corn cob, cotton stalks, soybean stalks, chaff, weeds, branches, leaves, sawdust, bark and other solid wastes of crops as raw materials. Pressurized, densified, and formed into small rod-shaped solid particle fuel. Pellet fuel is made by extruding raw materials such as wood chips and straws by pressing rollers and ring die under normal temperature conditions. The density of raw materials is generally about 110-130kg/m3, and the density of the formed particles is greater than 1100kg/m3, which is very convenient for transportation and storage, and at the same time, its combustion performance is greatly improved.

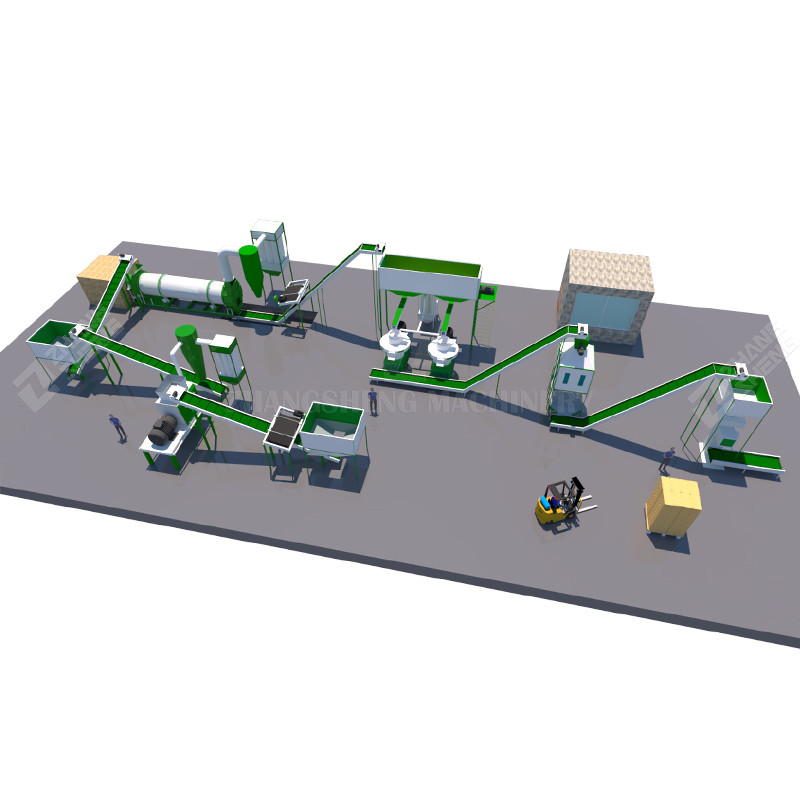

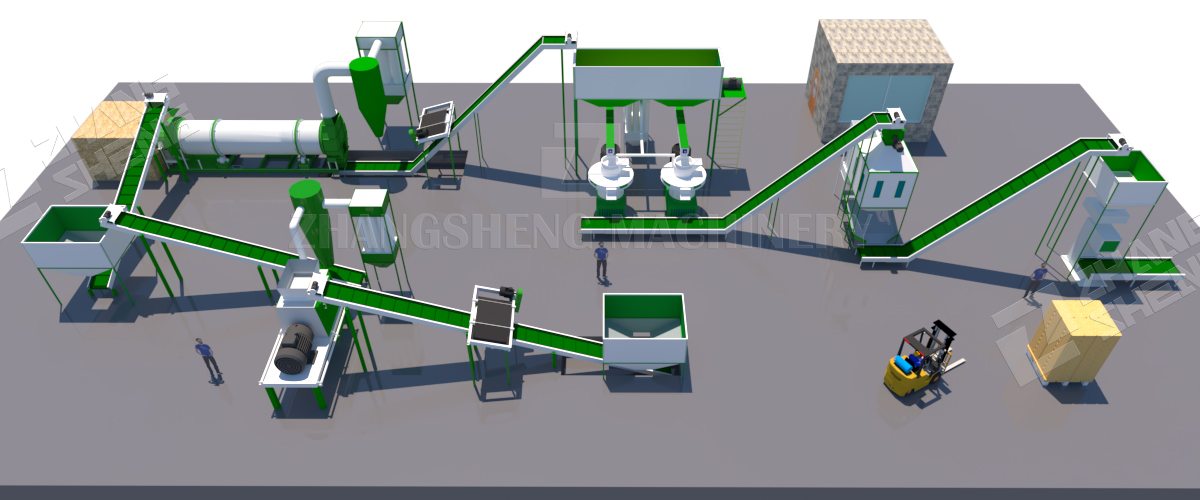

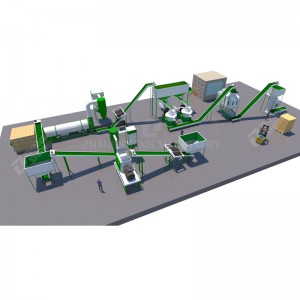

A complete straw pellet machine production line probably needs the following steps: crushing - drying stage - granulation stage - cooling stage - packaging stage.

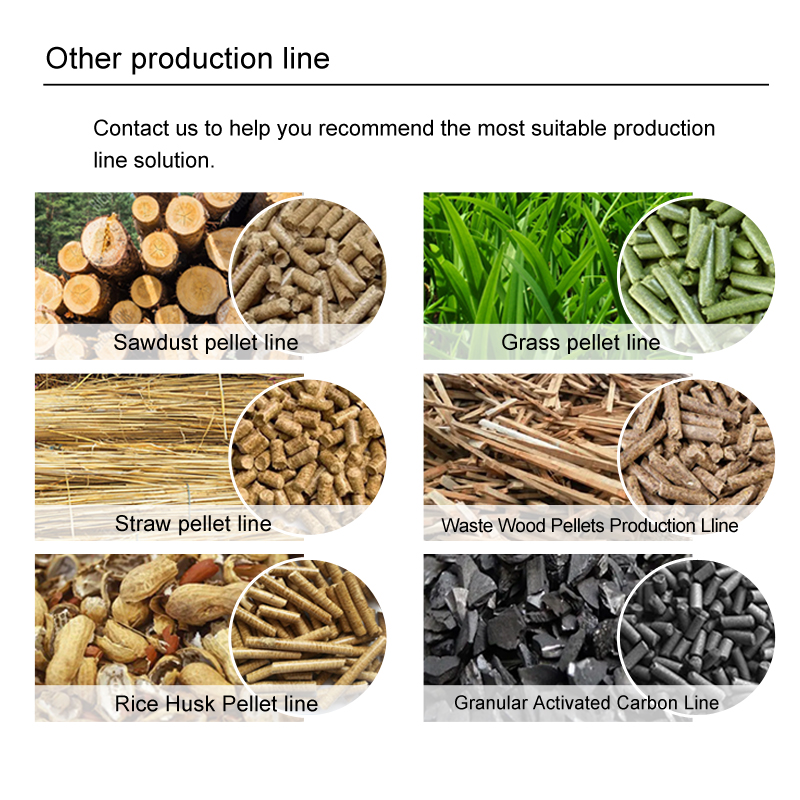

Biomass pellet equipment can use agricultural and forestry processing wastes, such as sawdust, rice straw, rice husk, bark and other biomass as raw materials, which can be solidified into high-density pellet fuel after pretreatment and processing. Biomass pellet machine is a popular pellet fuel processing equipment in the market at present. Biomass pellets are mainly used for industrial boilers, household heating, and biomass power stations.. There are many factors that determine the price. Let's discuss it in detail.

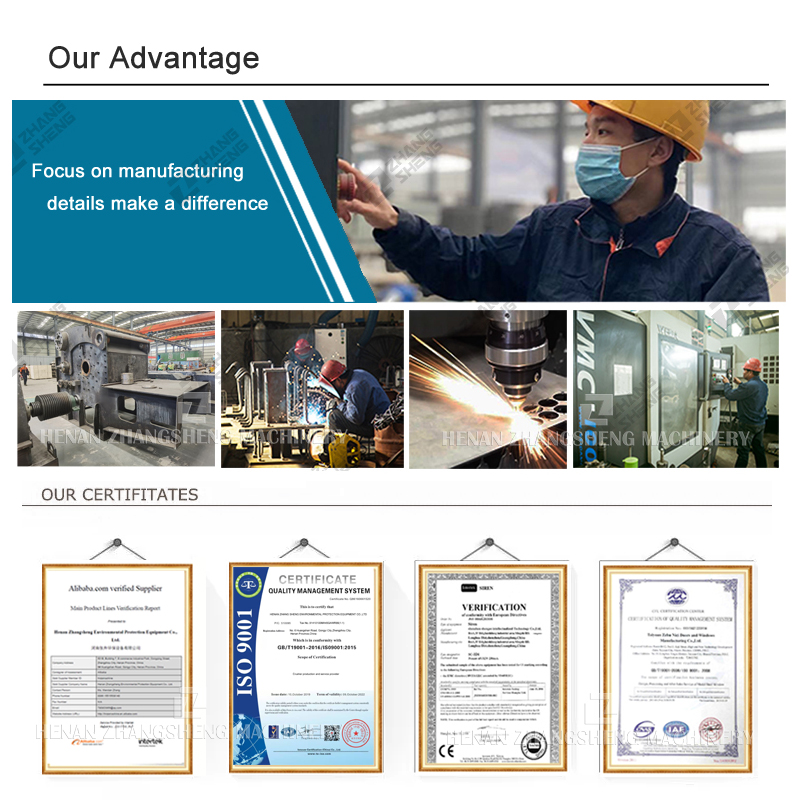

Product quality: All products of Zhangsheng brand are striving for perfection, each machine has been strictly inspected by technicians, and each part has been repeatedly tested, so you can buy each product of Zhangsheng brand with confidence! Now we advocate environmental protection, and the market of sawdust particles is so good, why do you hesitate? If you don't pay close attention to the investment of such a profitable project, you will have no choice but to regret the rest!

Service quality: At present, biomass energy industry is very popular and in the initial stage of development. Therefore, there are many equipment manufacturers with different quality levels, various types and sizes. Then the market price will change greatly. The old manufacturer has high technology, high equipment assembly precision and good stability, but the price will certainly be high. As the saying goes, you get what you pay. It is suggested that durable production equipment must be selected from manufacturers with good, stable and high-quality service support.

Different screens can be replaced according to different materials crushed by customers, and dust removal devices can be assembled according to requirements. The rotor has undergone a number of precision tests such as static balance, dynamic balance and vibration to ensure more stable operation, lower noise and better performance.

According to the feed and discharge moisture, calculate the required evaporation, select the diameter of the drum and the model of the hot blast stove. The main moisture in this section is 20%-60% for wood drying to 10-18%, and the hot air enters the drying cylinder from the hot blast stove. The material enters from the feeding port and is lifted by the lifting plate in the dryer, and then the hot air contacts the material to take away the moisture in the material, and the material comes out from the discharging port. propulsion. A tumble dryer cannot work alone. Generally, it needs to be equipped with a heat source, a fan, a Shakeron, and sometimes a dust removal device. The body of the tumble dryer itself is composed of a cylinder, a feeding port, a gear ring, and an aperture.

The biomass wood chip raw material falls vertically from the feeding port, and the material is continuously and uniformly distributed on the surface of the inner cavity of the mold (the contact surface between the pressing roller and the mold) through the rotation of the pressing roller. The material passes through the holes of the mold (holes evenly distributed on the inner surface of the mold). In this process, the material is subjected to high pressure and high temperature, resulting in physical changes or appropriate chemical changes (according to the material), which promotes the powdery material to form a continuously elongated cylindrical solid body, which is then cut off by a broken knife and discharged from the discharge port. The compaction process of the granules is completed.

Flow cooling is adopted by our pellet cooler. The pellet can be cooled and dried from high temperature and high humidity.There is a sliding valve mechanism to discharge the output.Temperature of the output could be close to the room temperature, like +3-5 Cdifference. The cooled particles is not higher than room temperature +3-5°C. Large capacity , satisfying cooling effect, more automation, lower noise, and fewer maintenance.

Note: This is a conventional simple biomass pellet production line, we can customize different pellet production plans for you according to different sites, raw materials, output and budget. As a leading pellet machine manufacturer in China, ZhangSheng has rich experience in pellet machine manufacturing, and can build a unique pellet mill for you according to the actual situation.

1. Are you a factory or a trading company?

We have our own factory. we have 20 years of experience in the pellet line manufacturing. "Market our own products" reduces the cost of intermediate links. OEM available according to your raw materials and output.

2. Which raw materials can be made into biomass pellets? If any requirements?

Raw material ca be wood waste, logs, tree branch , straw, stalk, bamboo, etc including fiber.

But the material for directly making wood pellets is sawdust with a diameter of no more than 8mm and moisture content of 12%-20%.

so if your material is not Sawdust and moisture is more than 20%, you need other machines, such as wood crusher,wood hammer mill and dryer etc.

3. I know very little about pellet production line, how to choose the most suitable machine?

Do not worry. We have helped a lot of beginners. Just tell us your raw material, your capacity (t/h) and the size of the final pellet product, we will choose the machine for you according to your specific situation.